- SolutionsMaintenance

Fleet maintenance software for vehicles and equipment

ComplianceEverything you need to keep your fleet compliant with the DOT

InspectionsVehicle inspection software that keeps you compliant and cuts costs

ReportingAccess the vital data you need to optimize the performance of your fleet

Fuel ManagementTrack fuel usage in real time and maximize profitability through fuel cost tracking

IntegrationsSee all - CustomersFeatured Case StudiesSee all

![Spartan Logistics]() Spartan Logistics

Spartan LogisticsSpartan Logistics is a safer, more efficient business by keeping their maintenance up and costs down with Whip Around.

View case study![Monster Tree Service]() Monster Tree Service

Monster Tree ServiceWhip Around gives Monster Tree Service visibility on vehicle & equipment location, condition, what work is due and what has been completed

View case study![Northwest Repossession]() Northwest Repossession

Northwest RepossessionNorthwest Repossession saves tens of thousands of dollars every year by staying totally compliant with Whip Around.

View case study![M. Pittman Enterprises]() M. Pittman Enterprises

M. Pittman EnterprisesThe team at M. Pittman turned to Whip Around for a digital solution to take the guesswork out of their preventive maintenance process.

View case study - ResourcesFeatured ContentSee all

![eBook: Fleet preventive maintenance: Why (and how) to prioritize it]() eBook: Fleet preventive maintenance: Why (and how) to prioritize it

eBook: Fleet preventive maintenance: Why (and how) to prioritize itEverything you need to make preventive maintenance a priority for your fleet.

View eBook![eBook: Creating a preemptive culture of safety, compliance, and preventive maintenance]() eBook: Creating a preemptive culture of safety, compliance, and preventive maintenance

eBook: Creating a preemptive culture of safety, compliance, and preventive maintenanceHow to build a preemptive culture of safety in six steps.

View eBookResource Type - Pricing

Fleet maintenance software for vehicles and equipment

Whip Around makes maintaining your fleet effortless. No more sorting through paper or spreadsheets, or juggling outdated systems. Stay on top of asset maintenance with a single, uncomplicated platform that makes your fleet more productive, effective, compliant, and safe.

Whip Around covers the entire fleet maintenance process

Get your team on the same page. Improve communication and automate your maintenance workload with a fleet maintenance system you can trust with the details.

Set up service schedules for each asset based on distance traveled, hours run, or time in service. It only takes moments, and once you set up a service schedule, you don’t have to think about it again. You’ll receive an alert when a service is due.

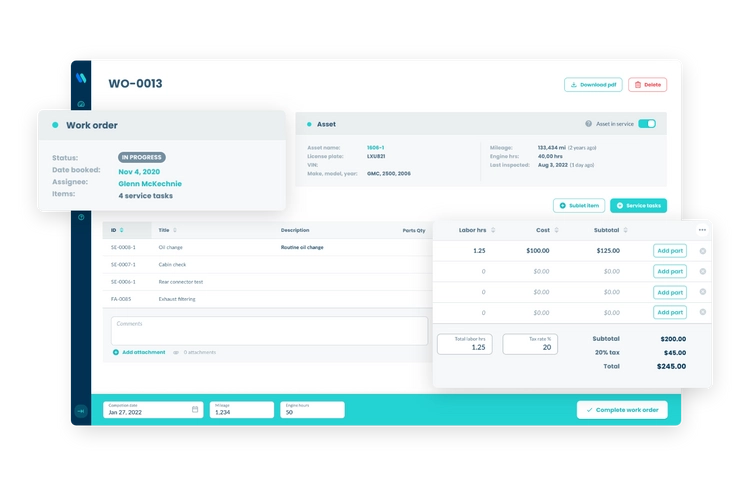

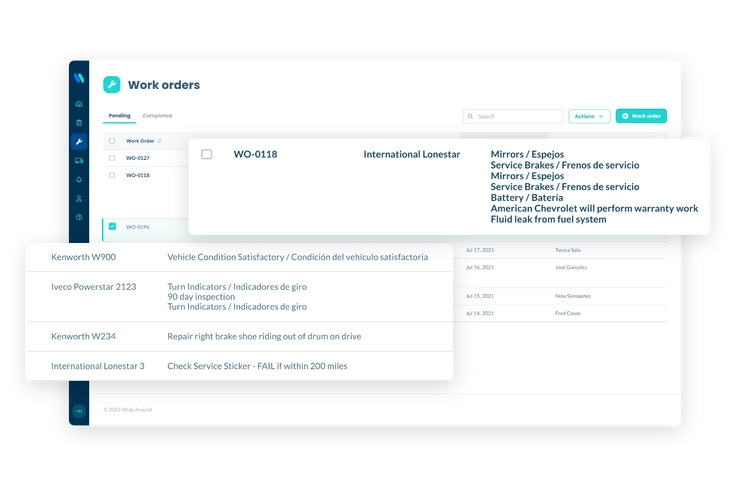

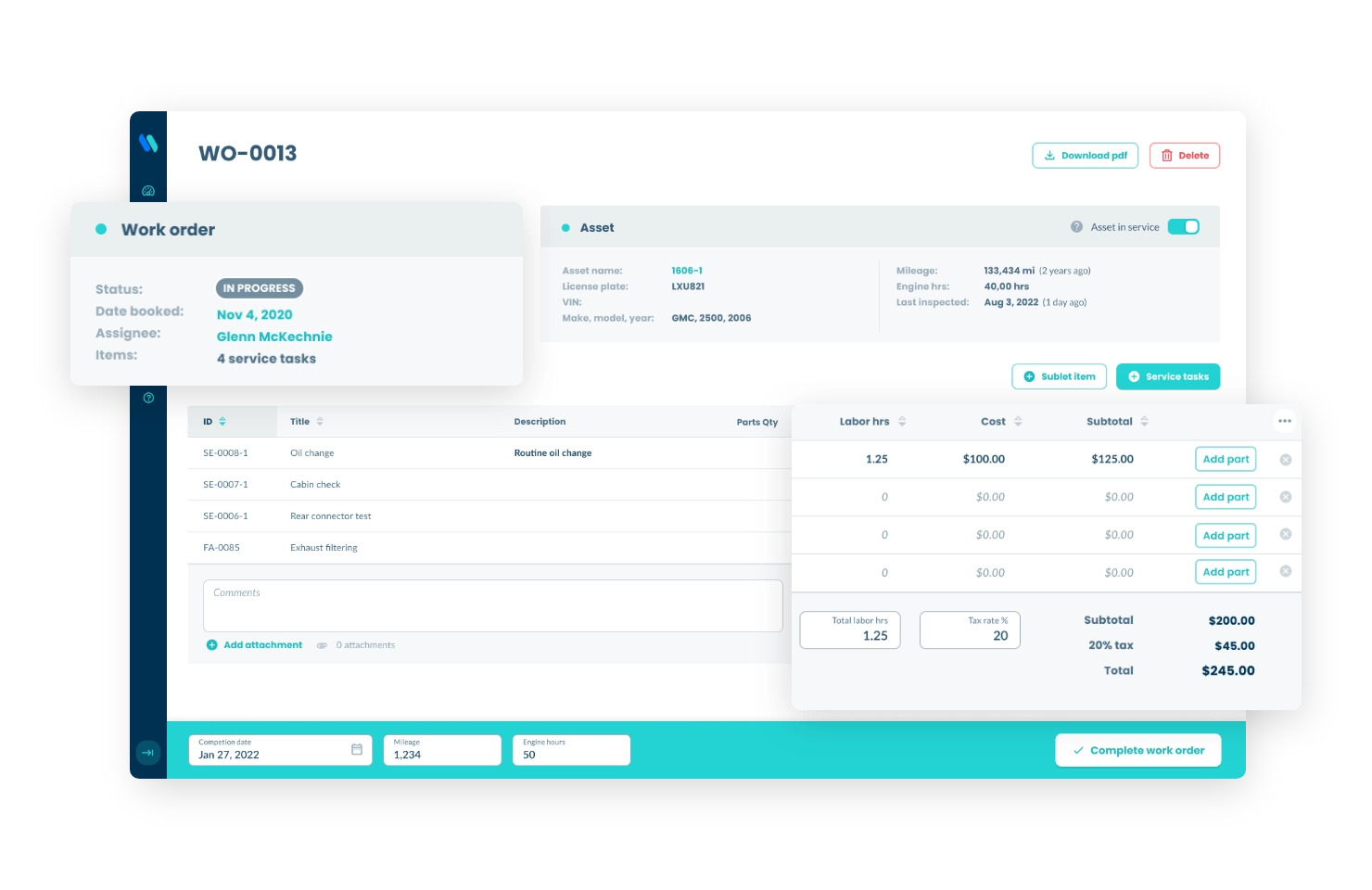

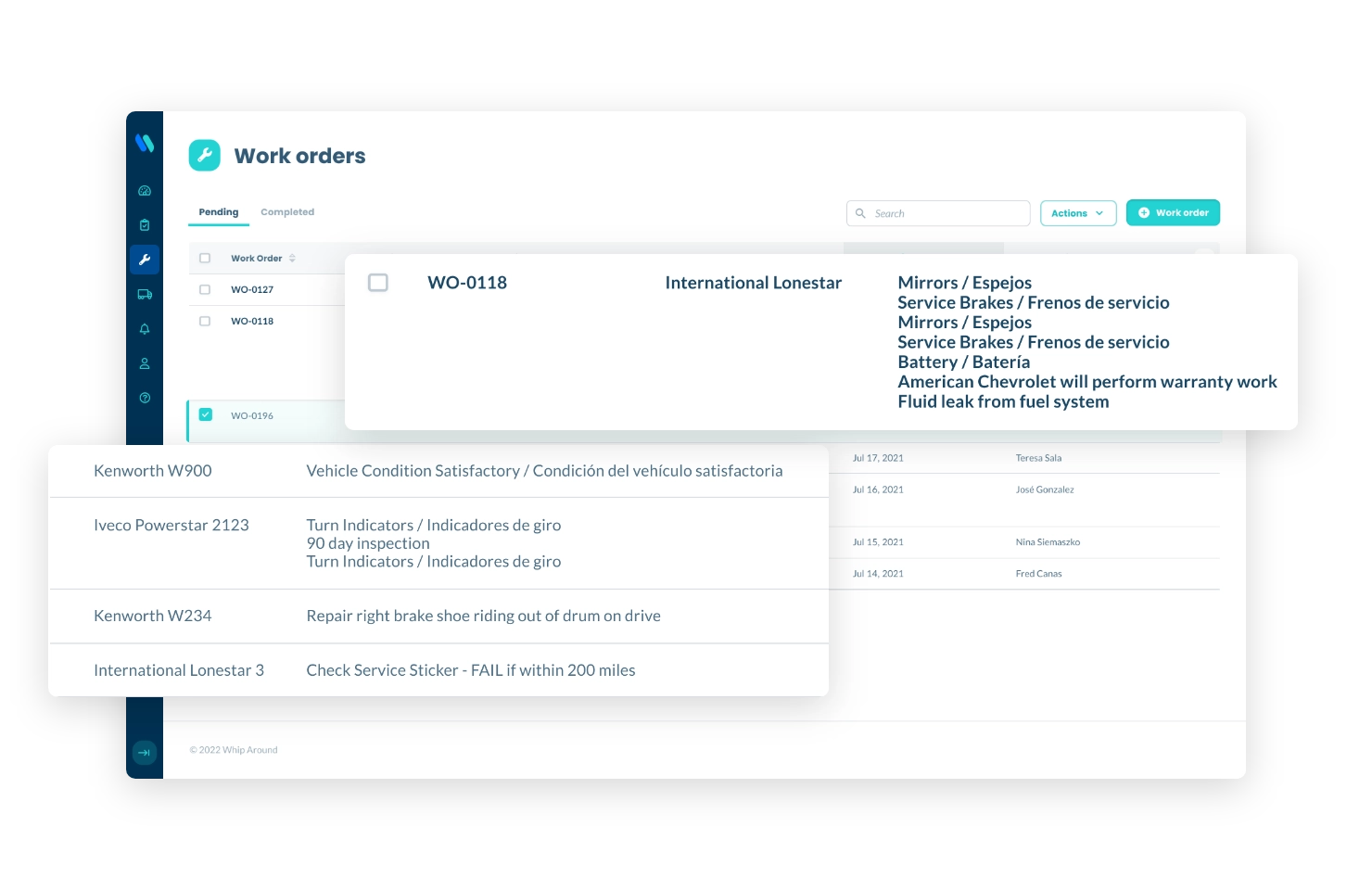

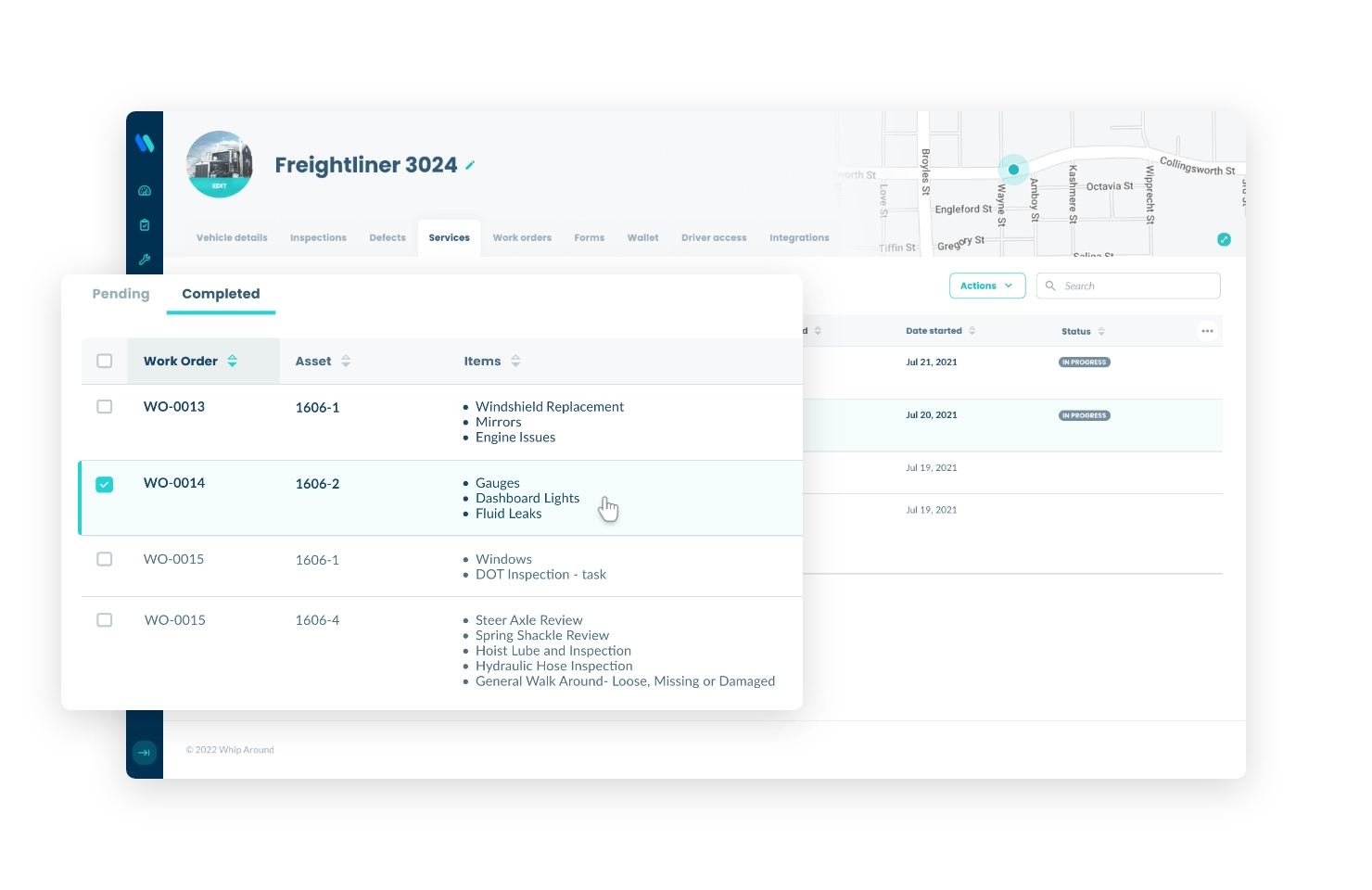

When a defect is found, creating an electronic work order for in-house or external mechanics is no problem. Whip Around even lets you know if a vehicle or machine has outstanding faults that can be added to the work order.

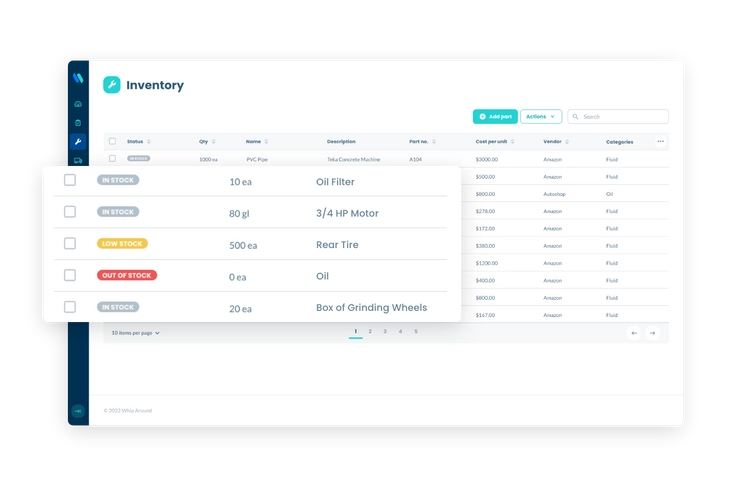

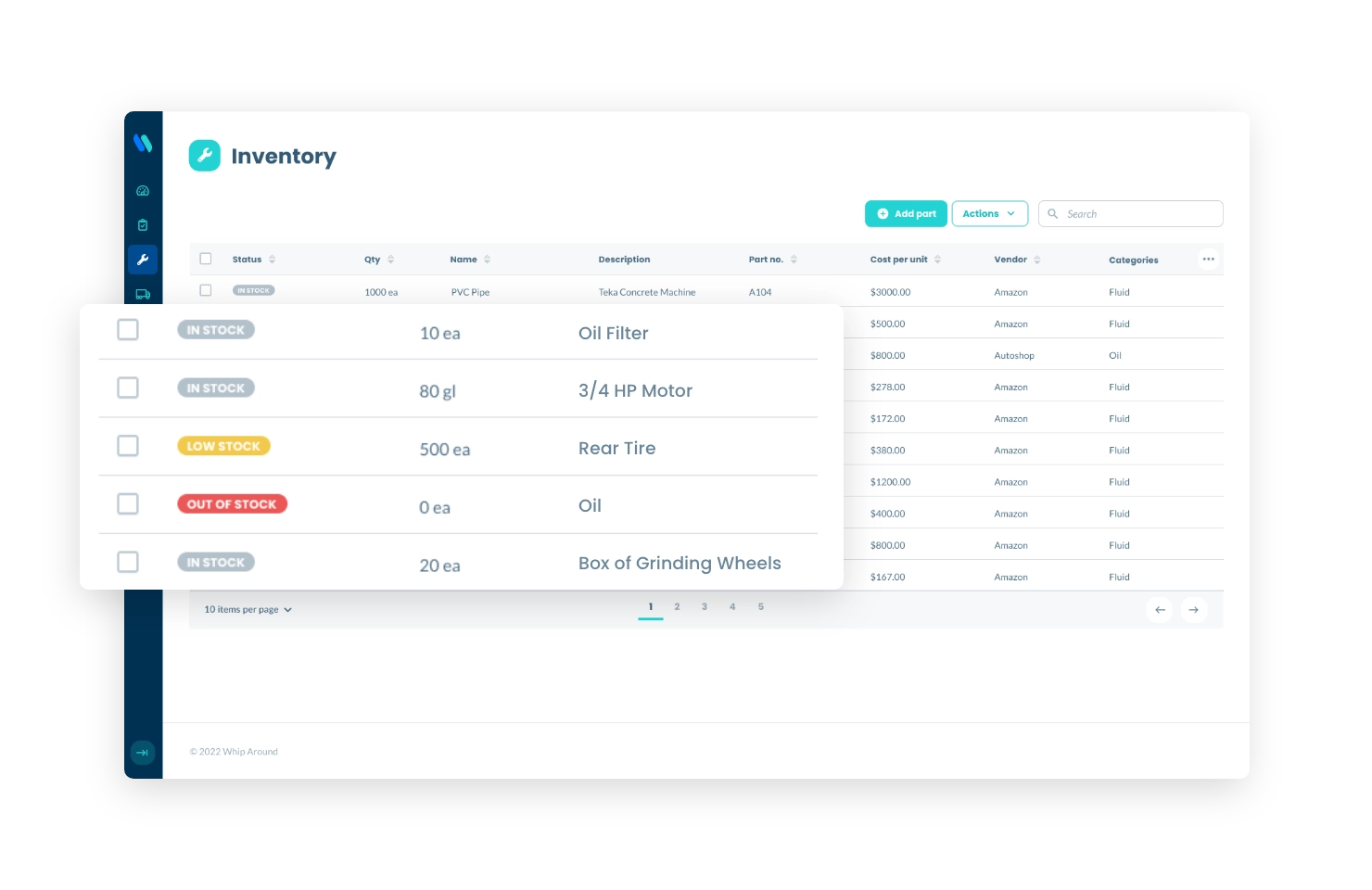

Never run out of what you need. Whip Around makes inventory management a breeze. Add parts to work orders and see their associated cost with repairs and service. When a part gets added to a work order, it’s instantly subtracted from your inventory.

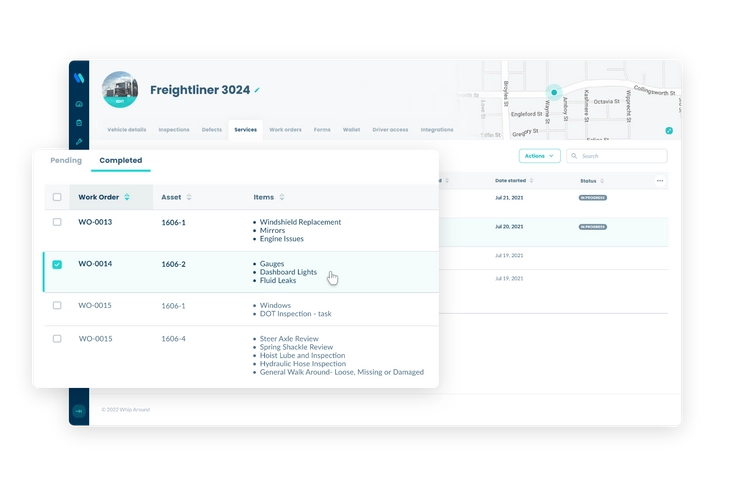

Keeping a detailed service history shouldn’t require documenting physical inspection forms and work orders in a spreadsheet. With Whip Around, service histories are updated automatically and easily accessible.

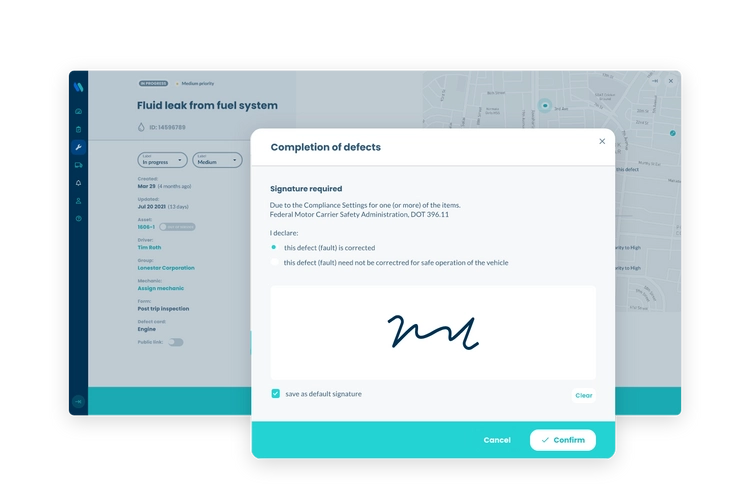

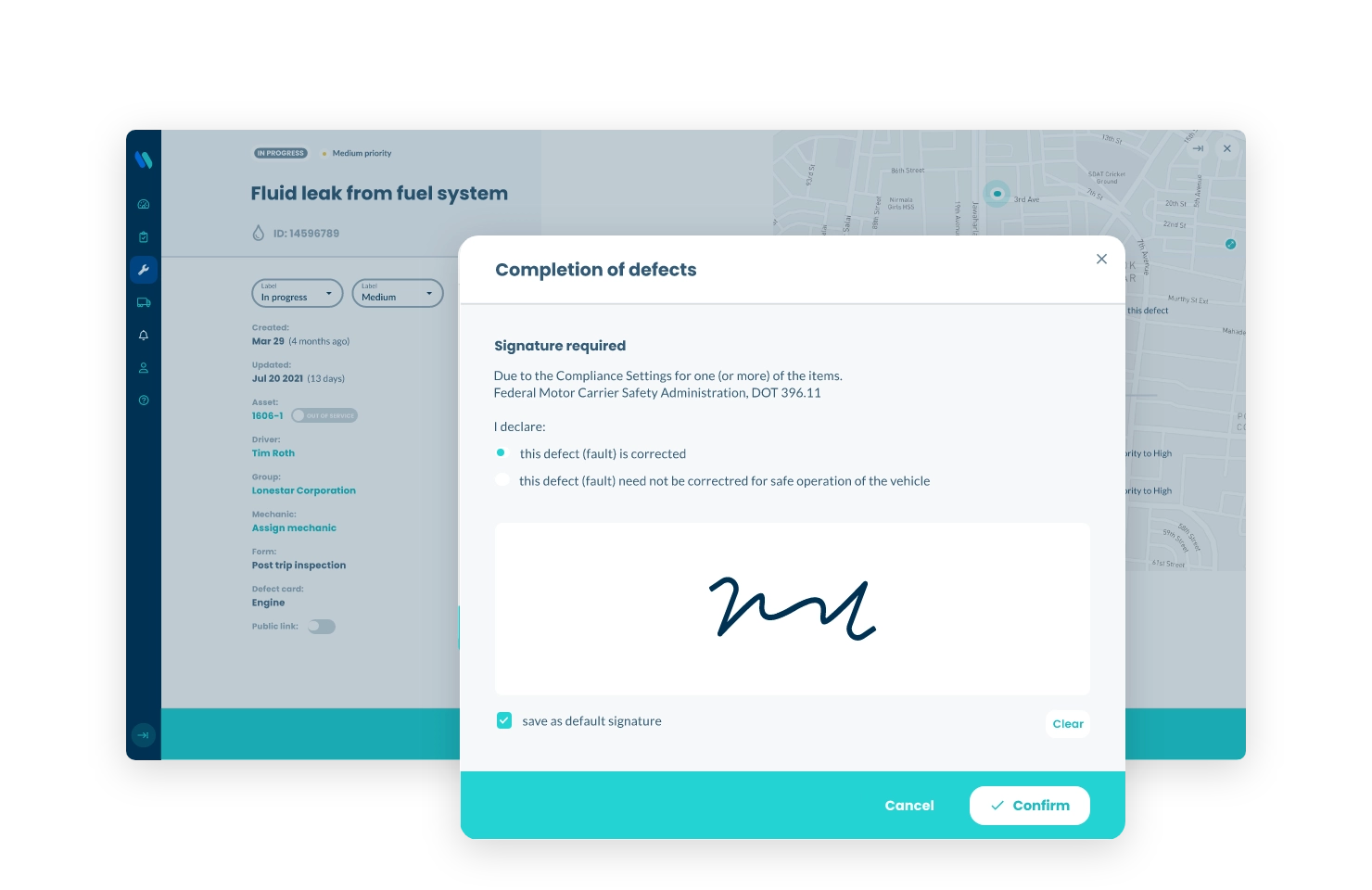

Corrected faults require a mechanic’s signature. Mechanics provide an e-signature right in the app, adding it to an asset’s profile. Instantly access an asset’s service history, along with the mechanic who performed the service.

A preventive maintenance system that drives overall fleet health

Timely information is the key to effective fleet maintenance. Whip Around helps you monitor the condition of each vehicle and piece of equipment, offering these crucial benefits to your business.

Discover potential problems before they become show-stopping breakdowns that dig into your bottom line. Your assets will be in tip-top shape, which means they’ll operate more efficiently for a longer period.

Log and track all your asset maintenance, and easily see a vehicle's maintenance history. Never wonder when was the last time a truck had its oil changed, wheels rotated, or brake pads replaced.

Take downtime into your own hands. By keeping everything running at peak efficiency and alerting you when service is due, fleet maintenance software equips you to be intentional about when equipment needs to be taken out of commission.

Preventative maintenance greatly maximizes the lifespan of your assets. With Whip Around, you’re equipped to perform regular, timely service on your equipment with an efficient, no-hassle workflow.

A robust fleet maintenance system should stop you from running from one emergency to another. Know what needs immediate attention and what can be taken care of when the time and budget allow.